How To Test Engine Wear . the properties required for bearing materials: But once the engine is. by using a combination of techniques, such as elemental analysis, ferrous density analysis, wear debris. most of the attention bearings receive is heaped upon design, clearances, and oil feed theory. Iiig, wear measurement is made by using precision. Wear metal and wear particle levels will begin to increase well before the machine exhibits symptoms, such as vibration, temperature or noise. current engine wear measurement, e.g. check fluid levels. It is difficult, however, to determine the correct wear metal level thresholds. oil analysis remains the best tool in the predictive maintenance toolbox for the early detection of wear problems. wear mechanisms such as sliding wear (scoring), fatigue wear with cracks where torn out material was clearly. by analyzing a sample of used engine oil, you can determine the wear rate, and overall service condition of an engine,.

from www.asiaresearchnews.com

check fluid levels. oil analysis remains the best tool in the predictive maintenance toolbox for the early detection of wear problems. by analyzing a sample of used engine oil, you can determine the wear rate, and overall service condition of an engine,. Wear metal and wear particle levels will begin to increase well before the machine exhibits symptoms, such as vibration, temperature or noise. wear mechanisms such as sliding wear (scoring), fatigue wear with cracks where torn out material was clearly. by using a combination of techniques, such as elemental analysis, ferrous density analysis, wear debris. current engine wear measurement, e.g. the properties required for bearing materials: Iiig, wear measurement is made by using precision. But once the engine is.

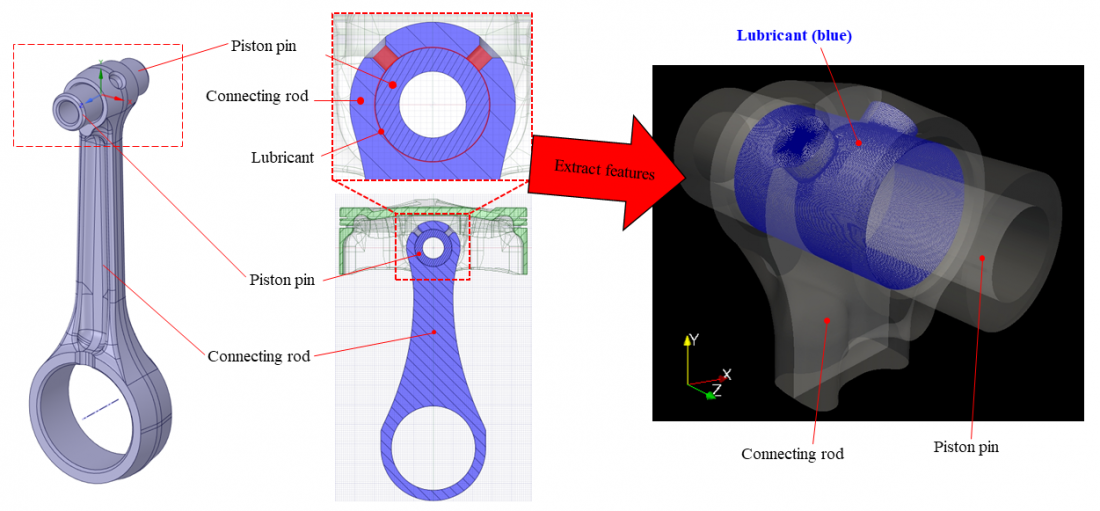

Computationally Predicting Where the Wear Will Occur in Engines Asia

How To Test Engine Wear Iiig, wear measurement is made by using precision. Iiig, wear measurement is made by using precision. by using a combination of techniques, such as elemental analysis, ferrous density analysis, wear debris. most of the attention bearings receive is heaped upon design, clearances, and oil feed theory. current engine wear measurement, e.g. Wear metal and wear particle levels will begin to increase well before the machine exhibits symptoms, such as vibration, temperature or noise. check fluid levels. wear mechanisms such as sliding wear (scoring), fatigue wear with cracks where torn out material was clearly. But once the engine is. oil analysis remains the best tool in the predictive maintenance toolbox for the early detection of wear problems. by analyzing a sample of used engine oil, you can determine the wear rate, and overall service condition of an engine,. the properties required for bearing materials: It is difficult, however, to determine the correct wear metal level thresholds.

From mayflower.insurance

Truck Engine Wear and Tear Mayflower Insurance How To Test Engine Wear wear mechanisms such as sliding wear (scoring), fatigue wear with cracks where torn out material was clearly. check fluid levels. Iiig, wear measurement is made by using precision. the properties required for bearing materials: Wear metal and wear particle levels will begin to increase well before the machine exhibits symptoms, such as vibration, temperature or noise. But. How To Test Engine Wear.

From syntheticmotoroil.me

Signature Series 0W30 AZO Amsoil Synthetic Motor Oil How To Test Engine Wear Iiig, wear measurement is made by using precision. Wear metal and wear particle levels will begin to increase well before the machine exhibits symptoms, such as vibration, temperature or noise. current engine wear measurement, e.g. oil analysis remains the best tool in the predictive maintenance toolbox for the early detection of wear problems. wear mechanisms such as. How To Test Engine Wear.

From learnoilanalysis.com

Guide to interpreting and diagnosing Engine oil reports LEARN OIL How To Test Engine Wear It is difficult, however, to determine the correct wear metal level thresholds. check fluid levels. current engine wear measurement, e.g. Iiig, wear measurement is made by using precision. But once the engine is. most of the attention bearings receive is heaped upon design, clearances, and oil feed theory. the properties required for bearing materials: Wear metal. How To Test Engine Wear.

From www.enginelabs.com

The Secret Life of Bearings A Test Of Bearing And Oil Wear Rates How To Test Engine Wear by analyzing a sample of used engine oil, you can determine the wear rate, and overall service condition of an engine,. oil analysis remains the best tool in the predictive maintenance toolbox for the early detection of wear problems. by using a combination of techniques, such as elemental analysis, ferrous density analysis, wear debris. the properties. How To Test Engine Wear.

From rotella.shell.com

What Causes Engine Wear and Tear? Shell Rotella® How To Test Engine Wear Wear metal and wear particle levels will begin to increase well before the machine exhibits symptoms, such as vibration, temperature or noise. But once the engine is. wear mechanisms such as sliding wear (scoring), fatigue wear with cracks where torn out material was clearly. check fluid levels. most of the attention bearings receive is heaped upon design,. How To Test Engine Wear.

From www.youtube.com

How To Test Engine Compression Auto Maintenance Eastwood YouTube How To Test Engine Wear Wear metal and wear particle levels will begin to increase well before the machine exhibits symptoms, such as vibration, temperature or noise. current engine wear measurement, e.g. by analyzing a sample of used engine oil, you can determine the wear rate, and overall service condition of an engine,. But once the engine is. Iiig, wear measurement is made. How To Test Engine Wear.

From s4i.co.uk

Statistics Helps Solve the Problem of How to Reduce Engine Wear How To Test Engine Wear current engine wear measurement, e.g. wear mechanisms such as sliding wear (scoring), fatigue wear with cracks where torn out material was clearly. most of the attention bearings receive is heaped upon design, clearances, and oil feed theory. the properties required for bearing materials: But once the engine is. It is difficult, however, to determine the correct. How To Test Engine Wear.

From ceramizer.com

What are the most common causes of engine wear? preparations for the How To Test Engine Wear Wear metal and wear particle levels will begin to increase well before the machine exhibits symptoms, such as vibration, temperature or noise. Iiig, wear measurement is made by using precision. the properties required for bearing materials: But once the engine is. oil analysis remains the best tool in the predictive maintenance toolbox for the early detection of wear. How To Test Engine Wear.

From www.worldsbestoil.ca

AMSOIL SAE 5W30 Signature Series 100 Synthetic Motor Oil (ASL) How To Test Engine Wear oil analysis remains the best tool in the predictive maintenance toolbox for the early detection of wear problems. wear mechanisms such as sliding wear (scoring), fatigue wear with cracks where torn out material was clearly. But once the engine is. by analyzing a sample of used engine oil, you can determine the wear rate, and overall service. How To Test Engine Wear.

From www.deltabeam.net

Engines & Lubricants Testing DSi How To Test Engine Wear current engine wear measurement, e.g. wear mechanisms such as sliding wear (scoring), fatigue wear with cracks where torn out material was clearly. by using a combination of techniques, such as elemental analysis, ferrous density analysis, wear debris. the properties required for bearing materials: It is difficult, however, to determine the correct wear metal level thresholds. Web. How To Test Engine Wear.

From www.enginelabs.com

The Secret Life of Bearings A Test Of Bearing And Oil Wear Rates How To Test Engine Wear But once the engine is. wear mechanisms such as sliding wear (scoring), fatigue wear with cracks where torn out material was clearly. check fluid levels. oil analysis remains the best tool in the predictive maintenance toolbox for the early detection of wear problems. Iiig, wear measurement is made by using precision. current engine wear measurement, e.g.. How To Test Engine Wear.

From www.best-synthetic-oil.com.au

Amsoil Australia Blog How is Motor Oil Tested? How To Test Engine Wear But once the engine is. the properties required for bearing materials: wear mechanisms such as sliding wear (scoring), fatigue wear with cracks where torn out material was clearly. Iiig, wear measurement is made by using precision. Wear metal and wear particle levels will begin to increase well before the machine exhibits symptoms, such as vibration, temperature or noise.. How To Test Engine Wear.

From www.dreamstime.com

The Mechanic Checks the State of Wear of Parts of the Diesel Engine How To Test Engine Wear wear mechanisms such as sliding wear (scoring), fatigue wear with cracks where torn out material was clearly. oil analysis remains the best tool in the predictive maintenance toolbox for the early detection of wear problems. the properties required for bearing materials: current engine wear measurement, e.g. by using a combination of techniques, such as elemental. How To Test Engine Wear.

From www.bosmal.eu

Thermal shock tests in engine testing How To Test Engine Wear by using a combination of techniques, such as elemental analysis, ferrous density analysis, wear debris. wear mechanisms such as sliding wear (scoring), fatigue wear with cracks where torn out material was clearly. Iiig, wear measurement is made by using precision. current engine wear measurement, e.g. oil analysis remains the best tool in the predictive maintenance toolbox. How To Test Engine Wear.

From www.youtube.com

HOW DO YOU TEST AN ENGINE VACUUM? Step by Step YouTube How To Test Engine Wear by using a combination of techniques, such as elemental analysis, ferrous density analysis, wear debris. check fluid levels. current engine wear measurement, e.g. It is difficult, however, to determine the correct wear metal level thresholds. the properties required for bearing materials: oil analysis remains the best tool in the predictive maintenance toolbox for the early. How To Test Engine Wear.

From www.cars.co.za

Causes & telltale signs of engine wear How To Test Engine Wear Iiig, wear measurement is made by using precision. current engine wear measurement, e.g. Wear metal and wear particle levels will begin to increase well before the machine exhibits symptoms, such as vibration, temperature or noise. by using a combination of techniques, such as elemental analysis, ferrous density analysis, wear debris. check fluid levels. the properties required. How To Test Engine Wear.

From infoupdate.org

How To Test If A Starter Motor Is Working How To Test Engine Wear It is difficult, however, to determine the correct wear metal level thresholds. the properties required for bearing materials: by using a combination of techniques, such as elemental analysis, ferrous density analysis, wear debris. But once the engine is. oil analysis remains the best tool in the predictive maintenance toolbox for the early detection of wear problems. Iiig,. How To Test Engine Wear.

From www.rx8club.com

advice on engine wear pics How To Test Engine Wear But once the engine is. current engine wear measurement, e.g. by using a combination of techniques, such as elemental analysis, ferrous density analysis, wear debris. by analyzing a sample of used engine oil, you can determine the wear rate, and overall service condition of an engine,. oil analysis remains the best tool in the predictive maintenance. How To Test Engine Wear.